Air New Zealand orders part from Singapore, prints it in LA

Apr 12, 2019

Air New Zealand has made a significant decision to streamline its operations by sourcing a key component from Singapore. This part, essential for the airline's fleet maintenance, will be manufactured in Singapore, known for its advanced production capabilities. Once produced, the component will be shipped to Los Angeles, where Air New Zealand's maintenance facilities will print and assemble it for use. This strategic move not only enhances efficiency but also ensures that the airline can maintain its high safety and service standards. The collaboration highlights Air New Zealand's commitment to leveraging global resources for operational excellence.

Air New Zealand's Innovative Approach to Aircraft Parts

Air New Zealand has taken a remarkable step in modernizing its aircraft maintenance and repair processes. By ordering essential parts from Singapore and utilizing cutting-edge printing technology in Los Angeles, the airline is setting a new standard in efficiency and sustainability. This strategic move not only enhances operational capabilities but also aligns with the company's commitment to reducing its environmental footprint.

The Journey of Aircraft Parts

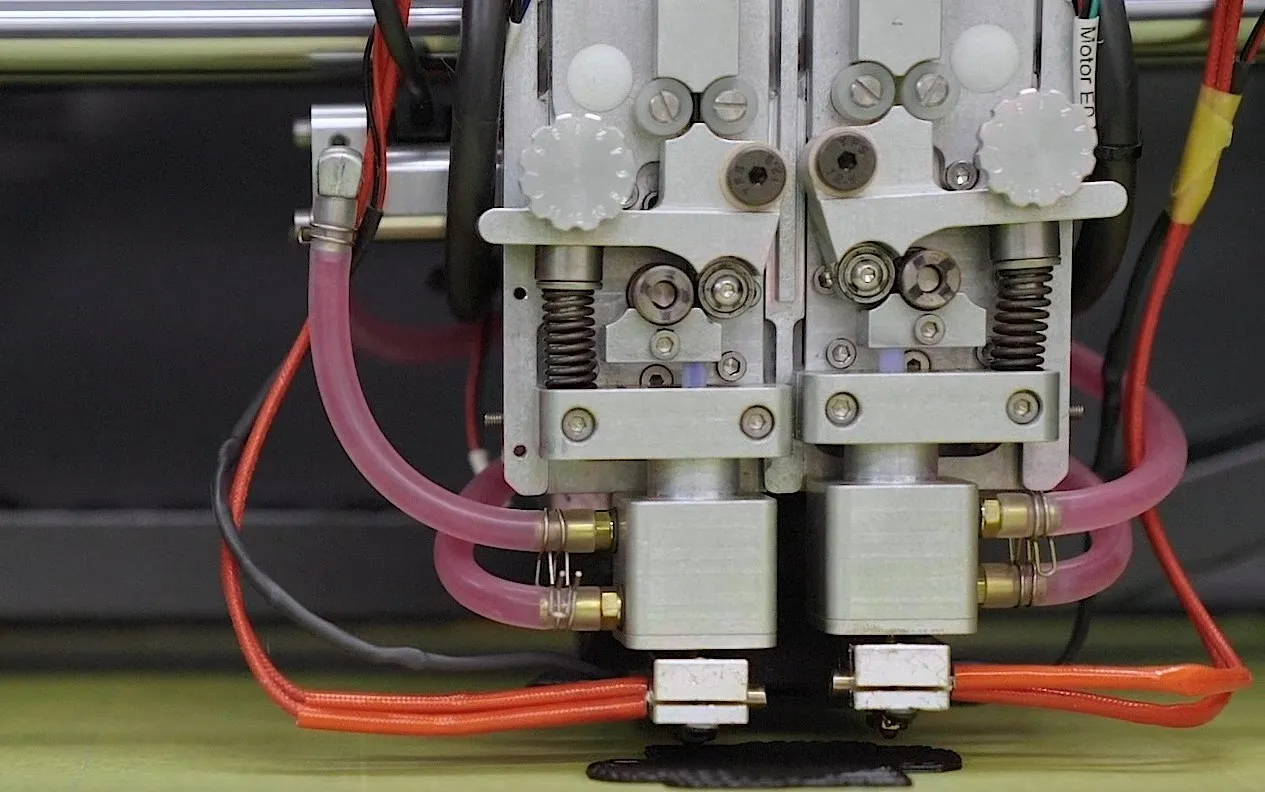

The journey of aircraft parts ordered by Air New Zealand begins in Singapore, a hub known for its advanced manufacturing capabilities. By sourcing high-quality components from this location, the airline ensures that it receives parts that meet stringent safety and performance standards. Once the parts are ordered, they are printed using state-of-the-art 3D printing technology in Los Angeles.

The Benefits of 3D Printing

3D printing has revolutionized the way companies approach manufacturing, especially in the aviation industry. Here are some key benefits that Air New Zealand is experiencing through this innovative process:

| Benefit | Description |

|---|---|

| Reduced Lead Time | 3D printing significantly reduces the time required to produce aircraft parts, allowing for quicker turnaround times. |

| Cost Efficiency | By printing parts on-demand, Air New Zealand can lower inventory costs and reduce waste associated with traditional manufacturing. |

| Customization | 3D printing allows for the customization of parts to meet specific aircraft requirements, ensuring optimal performance. |

| Lightweight Components | The ability to create lighter components contributes to fuel efficiency, which is a top priority for the airline. |

Environmental Impact

Air New Zealand is dedicated to sustainability, and this innovative approach to sourcing and manufacturing parts plays a crucial role in their environmental strategy. By utilizing 3D printing technology, the airline minimizes waste and reduces the carbon footprint associated with traditional manufacturing processes. This commitment to sustainability is reflected in their overall operational practices, making them a leader in eco-friendly aviation.

Collaboration with Local Industries

By partnering with manufacturers in Singapore and utilizing 3D printing technology in Los Angeles, Air New Zealand fosters collaboration within local industries. This not only supports economic growth but also encourages the sharing of knowledge and expertise in advanced manufacturing techniques. Such collaborations are essential for driving innovation in the aviation sector.

Future Prospects

As Air New Zealand continues to refine its aircraft maintenance processes, the airline is exploring further advancements in technology that can complement its current approach. The integration of artificial intelligence and machine learning in predictive maintenance is a potential area of growth. By analyzing data from aircraft operations, the airline can proactively address maintenance needs, reducing the likelihood of unexpected downtime.

Conclusion

Air New Zealand's decision to order parts from Singapore and print them in Los Angeles represents a forward-thinking approach to aircraft maintenance. This strategy not only improves efficiency and reduces costs but also aligns with the airline's commitment to sustainability and innovation. As the aviation industry evolves, Air New Zealand is likely to remain at the forefront, leveraging technology to enhance its operations while setting an example for others in the industry.

Key Takeaways

- Air New Zealand is enhancing operational efficiency by ordering parts from Singapore.

- 3D printing in Los Angeles offers significant benefits, including reduced lead time and cost efficiency.

- The airline's commitment to sustainability is demonstrated through innovative manufacturing processes.

- Collaboration with local industries fosters economic growth and drives innovation.

- Future advancements may include the integration of AI and machine learning for predictive maintenance.

In conclusion, Air New Zealand's innovative practices in sourcing and manufacturing aircraft parts highlight the importance of adapting to modern technology and sustainable practices. This strategic direction not only benefits the airline but sets a benchmark for the entire aviation industry.

```Related Articles

Explore Thailand: The Best Islands to Visit for Paradise, Adventure, and Relaxation

The Ultimate Guide to the Best Islands in Thailand for Your Next Getaway

Do babies need passports? How to get a passport for a newborn

How to get a U.S. passport fast: here’s how to expedite the process

What is Mobile Passport Control: 5 reasons why you should use it

SENTRI vs. Global Entry: A detailed guide

Do you need a passport to go to the Bahamas? Let’s find out

Do you need a passport to go to Mexico? A detailed guide

Do you need a passport to go to Canada? We got the answer

Do You Need a Passport for a Cruise: An Essential Travel Guide

Booster Seat Requirements: All the Rules to Follow in Your Rental Car

What Are the World’s Most Powerful Passports, and How Does Yours Rank?

How to Take a Passport Photo at Home: A Helpful Guide

You've got to have heart! Southwest's new livery

Your opinion: Should water be free on low cost carriers?

Young women bolder than guys as solo travellers