Airbus robots aim to improve efficiency and quality

Oct 02, 2019

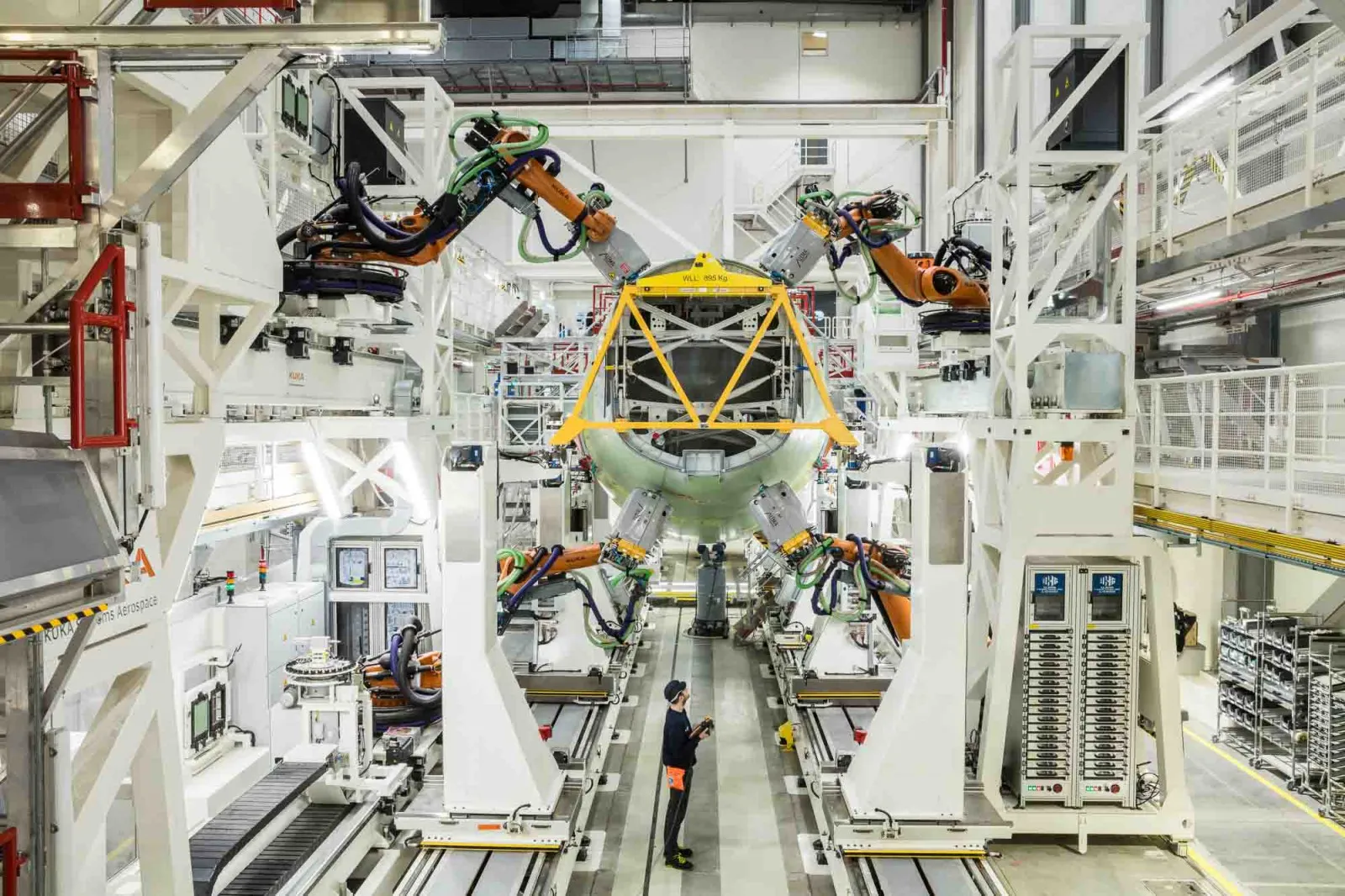

Airbus has integrated advanced robotic technologies into its manufacturing processes to enhance efficiency and quality. These robots are designed to perform repetitive tasks with precision, reducing human error and increasing production speed. By automating various stages of assembly, Airbus aims to streamline workflows and optimize resource utilization. This innovation not only improves the consistency of aircraft components but also allows human workers to focus on more complex tasks that require critical thinking and creativity. Ultimately, the use of robotics in Airbus facilities represents a significant step towards modernizing aerospace production and meeting the growing demands of the industry.

As the aerospace industry continues to evolve, "Airbus robots" are at the forefront of a technological revolution aimed at enhancing both efficiency and quality in aircraft manufacturing. By integrating cutting-edge robotics into their production lines, Airbus is setting new standards for operational excellence. This article delves into how these "automated systems" are reshaping the manufacturing landscape and the benefits they bring to the table.

Enhancing Manufacturing Efficiency

One of the primary goals of integrating robots into the manufacturing process is to significantly improve efficiency. "Airbus robots" are designed to handle repetitive tasks that would otherwise take a considerable amount of time if done manually. This leads to a reduction in production times and allows human workers to focus on more complex tasks that require specialized skills.

For example, robots can quickly perform tasks such as assembling components, painting, and even conducting inspections. This not only speeds up the production process but also ensures a high level of consistency in the quality of work performed. The automation of these processes leads to a streamlined workflow, which ultimately results in faster delivery times for aircraft.

Quality Control through Robotics

In addition to improving efficiency, "Airbus robots" play a critical role in enhancing quality control. By utilizing advanced sensors and algorithms, these robots can detect anomalies and defects in real time. This capability allows manufacturers to address issues immediately, preventing subpar products from reaching the market.

The implementation of robots in quality control processes also minimizes human error, which is often a significant factor in manufacturing defects. As a result, the overall quality of the finished aircraft improves, leading to heightened customer satisfaction and trust in the "Airbus brand".

Cost Reduction and Resource Management

Another significant advantage of using "Airbus robots" is the potential for cost reduction. While the initial investment in robotic technology can be substantial, the long-term savings can be significant. By automating labor-intensive tasks, Airbus can reduce labor costs and minimize the likelihood of expensive errors.

Moreover, robots can operate continuously without the need for breaks, vacations, or overtime pay, leading to enhanced productivity. This uninterrupted operation contributes to better resource management, allowing Airbus to allocate its workforce more effectively and focus on strategic growth initiatives.

Flexibility and Adaptability in Production

The adaptability of "Airbus robots" is another factor that enhances their value in manufacturing. In today’s rapidly changing market, the ability to pivot and adjust production lines quickly is crucial. Robots can be reprogrammed and equipped with different tools to handle various tasks, making them highly versatile.

This flexibility allows Airbus to respond more effectively to shifting consumer demands and market trends. For instance, if there is a sudden increase in demand for a specific aircraft model, the production line can be adjusted swiftly to accommodate this need without significant downtime.

Training and Workforce Development

As "Airbus robots" take on more responsibilities, there is a growing need for skilled workers who can manage and maintain these automated systems. This shift presents an opportunity for workforce development and training. Airbus is investing in training programs to ensure that employees are well-equipped to work alongside robots and utilize advanced technologies effectively.

By fostering a culture of continuous learning, Airbus not only enhances its operational capabilities but also empowers its workforce. Employees gain valuable skills that are applicable in various sectors, making them more competitive in the job market.

Future of Robotics in Aerospace Manufacturing

The integration of "Airbus robots" in manufacturing is just the beginning. As technology continues to advance, we can expect to see even more sophisticated robotic systems that will further revolutionize the industry. Innovations such as artificial intelligence (AI) and machine learning are poised to enhance the capabilities of these robots, making them even more efficient and intelligent.

In the future, we may witness the emergence of fully automated manufacturing lines that can operate with minimal human intervention. This could lead to unprecedented levels of efficiency and quality in aerospace manufacturing, setting new benchmarks for the entire industry.

Conclusion

In conclusion, the implementation of "Airbus robots" in aircraft manufacturing is a strategic move towards achieving greater efficiency and quality. By automating various processes, Airbus is not only enhancing its operational efficiency but also improving product quality and reducing costs. As the aerospace industry continues to evolve, the role of robotics will undoubtedly become more prominent, paving the way for a new era in manufacturing.

| Benefits of Airbus Robots | Details |

|---|---|

| Efficiency | Reduction in production time and streamlined workflows. |

| Quality Control | Real-time defect detection and minimized human error. |

| Cost Reduction | Lower labor costs and minimized risk of errors. |

| Flexibility | Ability to quickly adapt to changing production needs. |

| Workforce Development | Investment in employee training for advanced technology. |

As Airbus continues to innovate with "robotic technologies", it sets an example for others in the aerospace sector to follow, demonstrating that the future of manufacturing lies in the effective integration of automation and human expertise.

Related Articles

Explore Thailand: The Best Islands to Visit for Paradise, Adventure, and Relaxation

The Ultimate Guide to the Best Islands in Thailand for Your Next Getaway

Do babies need passports? How to get a passport for a newborn

How to get a U.S. passport fast: here’s how to expedite the process

What is Mobile Passport Control: 5 reasons why you should use it

SENTRI vs. Global Entry: A detailed guide

Do you need a passport to go to the Bahamas? Let’s find out

Do you need a passport to go to Mexico? A detailed guide

Do you need a passport to go to Canada? We got the answer

Do You Need a Passport for a Cruise: An Essential Travel Guide

Booster Seat Requirements: All the Rules to Follow in Your Rental Car

What Are the World’s Most Powerful Passports, and How Does Yours Rank?

How to Take a Passport Photo at Home: A Helpful Guide

You've got to have heart! Southwest's new livery

Your opinion: Should water be free on low cost carriers?

Young women bolder than guys as solo travellers