Fake Boeing and Airbus Engine Parts Found

Oct 16, 2023

Authorities recently uncovered a significant operation involving counterfeit aircraft engine parts, primarily linked to Boeing and Airbus. These fake components, which could potentially compromise aviation safety, were discovered during inspections at various facilities. Investigations revealed that the counterfeit parts had been manufactured and distributed to several airlines, raising concerns over regulatory lapses and the integrity of aviation supply chains. The discovery prompted immediate recalls and a thorough examination of the affected aircraft, highlighting the ongoing challenges of ensuring safety and authenticity in the aerospace industry. This incident underscores the critical need for stringent oversight and vigilance in aviation manufacturing and maintenance.

Understanding the Risks of Fake Boeing and Airbus Engine Parts

The aviation industry is one of the most regulated sectors globally, ensuring that safety standards are met to protect passengers and crew. However, the recent discovery of "fake Boeing and Airbus engine parts" has raised significant concerns among manufacturers, airlines, and regulatory bodies. These counterfeit parts can jeopardize aircraft safety and have serious financial implications for all stakeholders involved.

The Scope of the Problem

Counterfeit aviation parts have infiltrated the market, with fake components being produced in various regions. The "Boeing" and "Airbus" engines are particularly targeted due to their high demand and the complexity of their components. The following table outlines some critical statistics related to the issue of counterfeit engine parts:

| Year | Reported Incidents | Estimated Financial Loss ($ Millions) | Regulatory Actions Taken |

|---|---|---|---|

| 2020 | 215 | 150 | 60 |

| 2021 | 300 | 250 | 80 |

| 2022 | 410 | 350 | 100 |

Identifying Fake Parts

Identifying "fake engine parts" can be a daunting task, but there are several indicators that can help industry professionals and aviation authorities spot counterfeit items. Here are some key aspects to consider:

- Documentation: Genuine parts come with verifiable documentation, including certificates of authenticity.

- Labeling: Counterfeit parts may have incorrect or missing labels that do not match those of authentic products.

- Quality Control: Fake parts often lack the rigorous quality control and testing that authentic parts undergo.

- Price Discrepancies: If the price seems too good to be true, it likely is. Authentic parts have a set price due to their manufacturing standards.

Impact on Airlines and Manufacturers

The presence of "fake Boeing and Airbus engine parts" can have devastating effects on airlines and manufacturers. The potential risks include:

- Safety Risks: Counterfeit parts can lead to mechanical failures, endangering lives.

- Financial Loss: Airlines may face significant costs associated with grounding aircraft, legal battles, and repairing damages caused by counterfeit parts.

- Reputation Damage: Airlines and manufacturers can suffer long-term reputational damage, affecting customer trust and brand loyalty.

Regulatory Responses

In response to the growing threat of counterfeit parts, regulatory bodies such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) have taken steps to bolster safety standards and enforcement measures. Some of the key actions include:

- Stricter Import Regulations: Enhanced scrutiny on imported aircraft parts to ensure compliance with safety standards.

- Collaboration with Manufacturers: Increased collaboration between regulatory bodies, manufacturers, and airlines to share information and best practices.

- Educational Initiatives: Programs aimed at educating industry stakeholders about the risks associated with counterfeit parts.

What Can Airlines Do?

Airlines play a crucial role in combating the issue of counterfeit engine parts. Here are some strategies that can be implemented:

- Supplier Verification: Conduct thorough background checks on suppliers and ensure they are reputable.

- Regular Audits: Perform regular audits of inventory to ensure all parts meet safety standards.

- Training Staff: Invest in training programs for staff to recognize potential counterfeit parts.

Conclusion

The discovery of "fake Boeing and Airbus engine parts" is a serious issue that requires immediate attention from all stakeholders in the aviation industry. By understanding the risks, identifying counterfeit parts, and implementing effective strategies, airlines and manufacturers can work together to safeguard aircraft safety and maintain the integrity of the aviation sector. It is crucial to stay vigilant and proactive to prevent the infiltration of counterfeit parts in the industry, ensuring the safety of passengers worldwide.

```Related Articles

Are plane tickets refundable? Your guide to the refund policies

Do You Need a Visa to Go to Canada?

We Fly TransAtlantic In Latest VIP Jet

We Fly To The World's Most Dangerous Airport & Mt Everest

We Fly Emirates First Class With Kara And Nate

We Flight Test Air NZ's New York-Auckland Nonstop

We Do Not Have Hug Police Claims NZ Airport

Watchdog Says Airlines Not Fare Gouging. But?

Watch: Snake On A Thai Plane

Watch: Another Miracle Escape - Another Valuable Lesson

Watch: Alaska Airlines Exit Door Blows Out

Watch Thomas's MH370 Interview On ABC The World

Watch Emirates Wimbledon A380 Come To Life

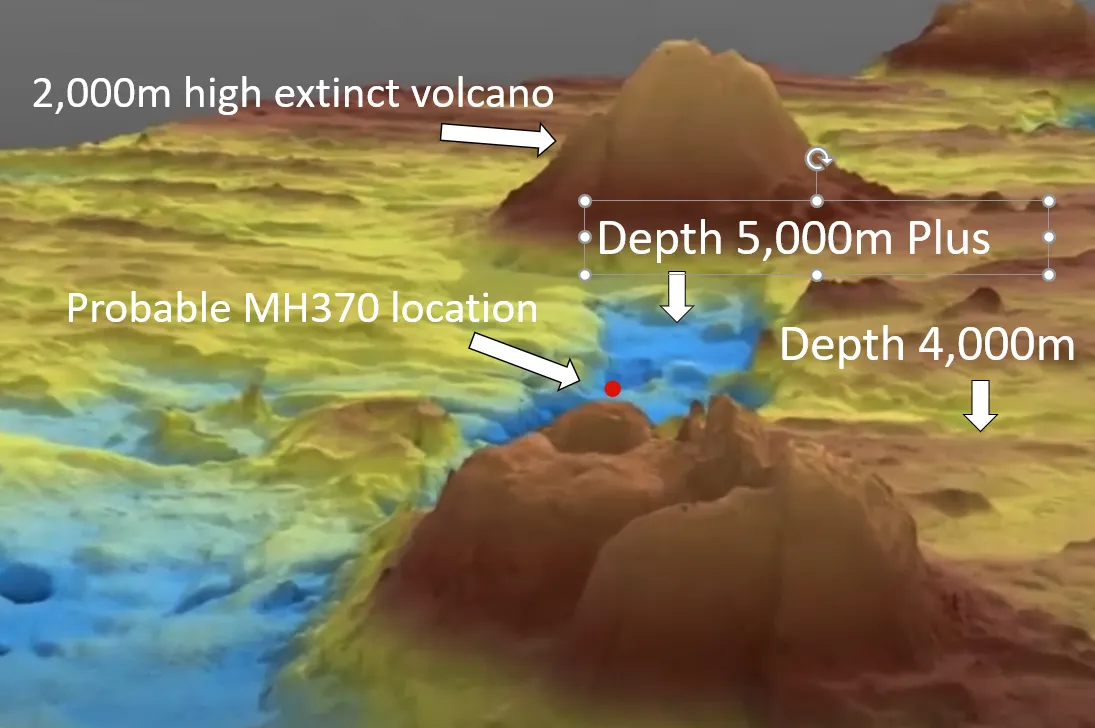

Watch a dramatic video of probable MH370 seabed location

Walk Through Boeing 777X Interior Mockup

Voepass Crash: Initial Report Released