Tiny maintenance robots could swarm over engines

Jul 18, 2018

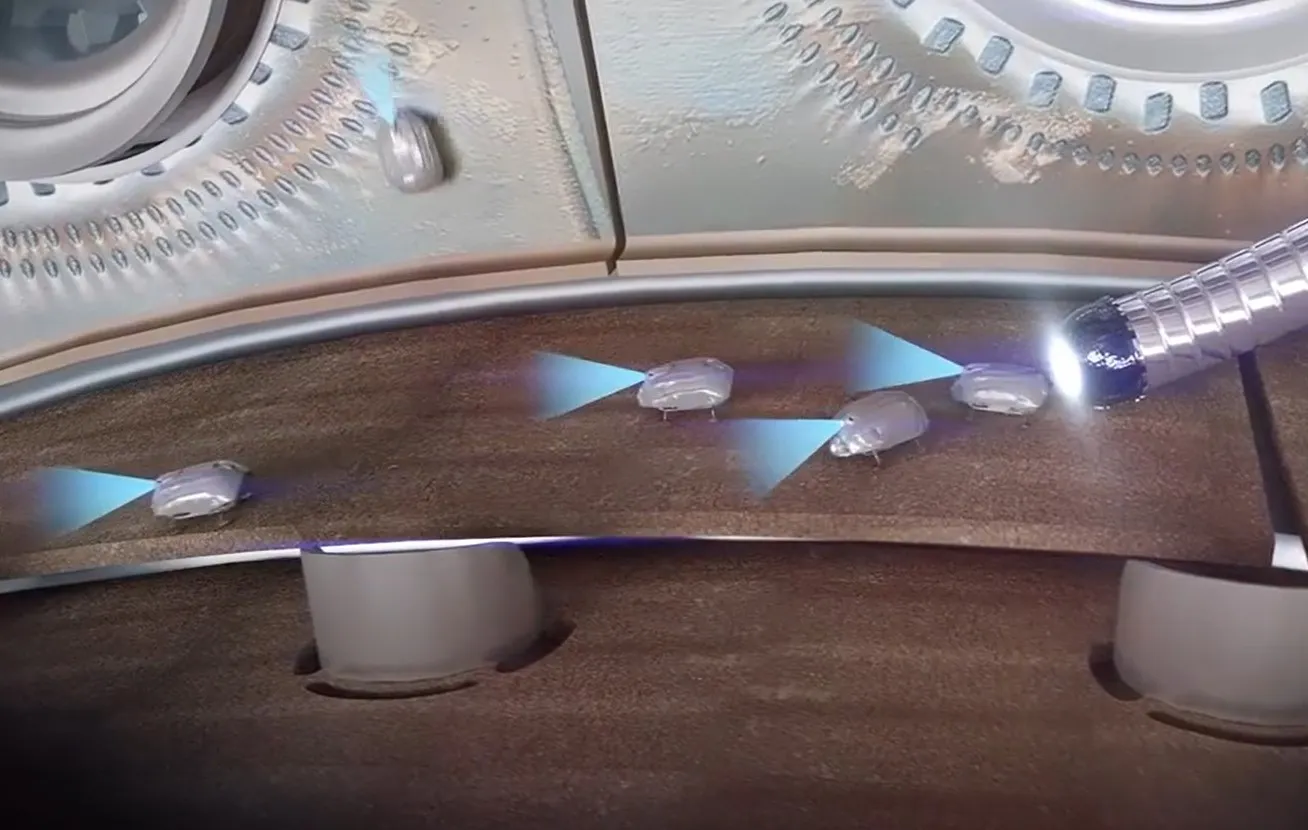

Tiny maintenance robots are designed to autonomously swarm over engines, efficiently performing inspections and repairs in hard-to-reach areas. These miniature machines utilize advanced sensors and algorithms to detect wear, leaks, and other issues, significantly reducing downtime and maintenance costs. Their collaborative behavior allows them to work in teams, sharing data and optimizing their tasks in real-time. By leveraging their small size and agility, these robots can navigate complex engine components with ease, ensuring thorough monitoring and upkeep. This innovative technology represents a significant leap forward in maintenance practices, enhancing reliability and reducing the need for extensive human intervention.

Tiny maintenance robots are revolutionizing the way we approach engine repairs and maintenance. These miniature technological marvels offer a new level of efficiency and precision, capable of swarming over engines to perform tasks that were once deemed too complex or labor-intensive for human technicians. As industries increasingly seek automation solutions, these robots are becoming indispensable tools in the maintenance landscape.

Understanding Tiny Maintenance Robots

Tiny maintenance robots are designed to navigate tight spaces and handle intricate tasks with agility. Their small size allows them to access areas that are typically hard to reach, making them ideal for engine maintenance in various industries, including automotive, aerospace, and manufacturing. These robots are equipped with advanced sensors and artificial intelligence, enabling them to diagnose issues and perform repairs autonomously.

Key Features of Tiny Maintenance Robots

These robots come with a range of features that enhance their functionality:

| Feature | Description |

|---|---|

| Autonomous Navigation | Equipped with sensors and AI for self-guided movement. |

| Diagnostic Capabilities | Can identify engine problems and suggest repairs. |

| Swarm Technology | Multiple robots can work together to tackle complex jobs. |

| Remote Operation | Can be controlled remotely for added convenience. |

Benefits of Using Tiny Maintenance Robots

The adoption of tiny maintenance robots in engine maintenance offers several advantages:

- Increased Efficiency: These robots can perform tasks faster than human workers, significantly reducing downtime.

- Precision Repairs: With their advanced sensors, they can execute repairs with high accuracy, minimizing the risk of human error.

- Cost-Effective: By automating maintenance tasks, companies can save on labor costs and reduce the need for extensive training.

- Enhanced Safety: Robots can handle hazardous tasks, protecting human workers from potential injuries.

Applications in Various Industries

Tiny maintenance robots are being integrated into a variety of industries:

Automotive Industry

In the automotive sector, these robots can inspect and maintain engines, ensuring optimal performance. They can efficiently clean components, check for wear and tear, and even assist in assembly lines.

Aerospace Sector

The aerospace industry benefits from tiny maintenance robots that can conduct routine inspections and repairs on aircraft engines. Their ability to access confined spaces is crucial in this highly regulated field.

Manufacturing

In manufacturing, tiny robots can monitor machinery and perform preventive maintenance. This proactive approach helps in avoiding costly breakdowns and production delays.

Challenges and Considerations

Despite their many advantages, the implementation of tiny maintenance robots does come with challenges:

- Initial Investment: The cost of developing and deploying these robots can be significant, which may deter some companies.

- Technical Limitations: While they are advanced, robots can struggle with complex repairs that require human intuition.

- Integration with Existing Systems: Companies may face challenges in integrating robots into their current maintenance workflows.

To overcome these hurdles, businesses must evaluate their specific needs and consider phased implementations that allow for gradual integration of these technologies.

The Future of Tiny Maintenance Robots

The future looks promising for tiny maintenance robots, with ongoing advancements in technology driving their capabilities. As artificial intelligence and machine learning continue to evolve, these robots will become even more intelligent, enabling them to learn from past maintenance tasks and improve over time.

Moreover, as the demand for automation increases across industries, the market for tiny maintenance robots is expected to grow significantly. Companies that adopt these technologies early may gain a competitive edge, boosting efficiency and reducing costs in their operations.

Conclusion

Tiny maintenance robots are poised to transform the way engine maintenance is performed. With their ability to navigate confined spaces, execute precise repairs, and work collaboratively, they offer numerous benefits that can enhance operational efficiency. As industries continue to embrace automation, the impact of these innovative robots will only grow, paving the way for a new era of maintenance solutions.

Related Articles

Explore Thailand: The Best Islands to Visit for Paradise, Adventure, and Relaxation

The Ultimate Guide to the Best Islands in Thailand for Your Next Getaway

Do babies need passports? How to get a passport for a newborn

How to get a U.S. passport fast: here’s how to expedite the process

What is Mobile Passport Control: 5 reasons why you should use it

SENTRI vs. Global Entry: A detailed guide

Do you need a passport to go to the Bahamas? Let’s find out

Do you need a passport to go to Mexico? A detailed guide

Do you need a passport to go to Canada? We got the answer

Do You Need a Passport for a Cruise: An Essential Travel Guide

Booster Seat Requirements: All the Rules to Follow in Your Rental Car

What Are the World’s Most Powerful Passports, and How Does Yours Rank?

How to Take a Passport Photo at Home: A Helpful Guide

You've got to have heart! Southwest's new livery

Your opinion: Should water be free on low cost carriers?

Young women bolder than guys as solo travellers