Boeing suspends production in Washington state facilities

Mar 23, 2020

Boeing has announced the suspension of production at its facilities in Washington state, a decision driven by various challenges including supply chain disruptions and a decrease in demand for commercial aircraft. This move affects several manufacturing lines and is part of the company's broader strategy to adapt to the evolving aerospace market. Employees will be impacted, with some facing temporary layoffs while others may be reassigned to different roles. Boeing aims to streamline operations and ensure long-term sustainability as it navigates an uncertain economic landscape and seeks to stabilize its production capabilities.

Boeing's decision to suspend production in its Washington state facilities has sent ripples through the aerospace industry, prompting discussions about the implications for the supply chain, workforce, and the company's future. This suspension is a significant move that reflects broader challenges within the aerospace sector, including supply chain disruptions and shifts in market demand.

Impact on Production and Workforce

The suspension of production affects several key facilities in Washington, including the Renton and Everett plants. The Renton facility, known for assembling the 737 series, and the Everett plant, home to the 747, 767, and 777X models, are critical to Boeing's operational capabilities. With production halted, thousands of employees are facing uncertainty. Boeing has communicated that it will prioritize the safety and well-being of its workforce during this challenging period.

| Facility | Aircraft Model | Number of Employees Affected |

|---|---|---|

| Renton | 737 | ~12,000 |

| Everett | 747, 767, 777X | ~30,000 |

The suspension is expected to last for an indefinite period, as the company assesses the situation. Boeing's management has indicated that they are committed to resuming operations but must navigate the complexities of the current market landscape. This decision has raised concerns among employees and stakeholders about job security and the long-term viability of the aerospace sector in Washington state.

Supply Chain Disruptions

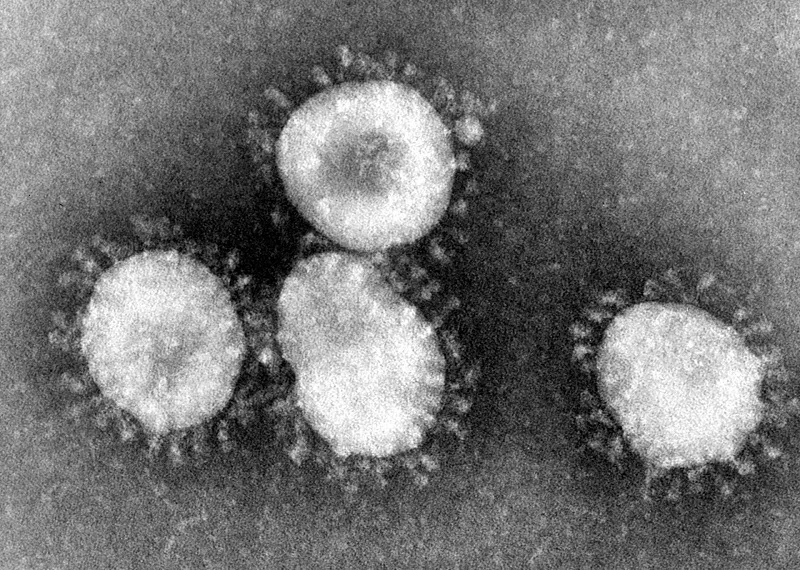

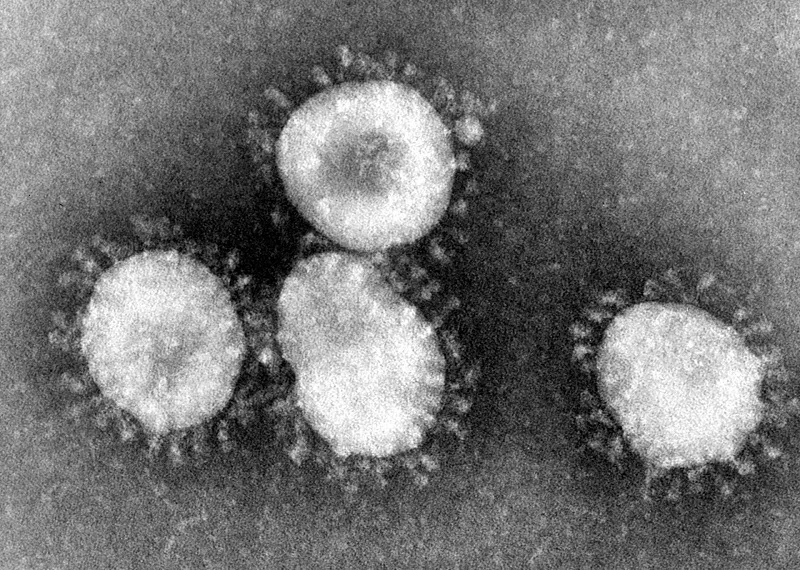

Boeing's production suspension is closely tied to ongoing supply chain challenges that have plagued the aerospace industry since the onset of the COVID-19 pandemic. Many suppliers have struggled to meet demand due to labor shortages, logistical issues, and increased costs of raw materials. This has led to a ripple effect, impacting Boeing's ability to produce aircraft on schedule.

One significant issue is the shortage of semiconductor chips, which are vital for various aircraft systems. The global chip shortage has affected not only Boeing but also other manufacturers across different sectors. As Boeing pauses production, it underscores the interconnected nature of the modern supply chain and highlights the need for resilience in the face of unforeseen disruptions.

Market Demand and Future Outlook

The suspension of production also raises questions about market demand for commercial aircraft. With the airline industry still recovering from the pandemic's impact, airlines have been cautious about expanding their fleets. Some analysts believe that demand for new aircraft may take longer to rebound than previously anticipated. Boeing's decision to halt production could be a strategic move to align its output with current market conditions.

According to industry reports, the commercial aviation market is expected to recover gradually, with a projected increase in air travel demand over the next few years. However, analysts caution that this recovery may be uneven, with different regions experiencing varying rates of growth. Boeing's ability to navigate this complex environment will be crucial in determining its long-term success.

Strategic Adjustments and Innovations

In light of the production suspension and market challenges, Boeing is exploring various strategic adjustments to enhance its competitiveness. The company is investing in digital transformation and innovative manufacturing processes to improve efficiency and reduce costs. These initiatives aim to streamline operations and prepare for future growth opportunities in the aerospace sector.

Furthermore, Boeing is focusing on sustainability efforts to address environmental concerns and comply with evolving regulations. The development of more fuel-efficient aircraft and the exploration of alternative fuels are central to Boeing's long-term strategy. These innovations could position the company favorably as the industry shifts towards greener solutions.

Conclusion

Boeing's suspension of production in its Washington state facilities is a significant development that has implications for the workforce, supply chain, and overall market dynamics. As the company navigates these challenges, its strategic decisions will be pivotal in shaping its future. The aerospace industry is currently at a crossroads, and stakeholders are closely watching how Boeing adapts to the evolving landscape.

In summary, the situation highlights the complexities of the aerospace supply chain and the need for companies like Boeing to remain agile in response to changing market conditions. As the industry seeks to recover and grow, the focus will likely be on innovation, sustainability, and resilience in operations.

Related Articles

Worried passengers swamp airline customer service centers

World’s longest flight was a night, a day and a night to remember.

World's Safest Airlines ; Qantas tops once again as safest airline for 2021

World's longest flight will only take 17 hours

Workplace watchdog orders Qantas to improve aircraft cleaning

Will the Airbus A380 be the next coronavirus victim?

Walsh to stay on as IAG cuts capacity by 75 percent

Virus sees China drop from third-biggest international market to 25th

Virgin offers quick way home for Aussies facing restrictions

Virgin Australia downgrade underscores need for government aid

US upgrades coronavirus travel warnings to Italy, South Korea, Iran

US expands Wuhan virus screening to Atlanta and Chicago

US CDC develops comprehensive plan to screen passengers to combat deadly virus.

US airlines warn of liquidity fears with $US10 billion monthly cash burn

US airlines suspend flights to South Korea

US airlines must fly to all ports to access aid payments